From precision cream skimming to complex industrial liquid clarification, Noe Tech International delivers high-performance separators backed by engineering expertise and trusted reliability.

Noe Tech International Pvt. Ltd. is a globally recognized manufacturer of high-performance centrifugal separators serving the dairy, food, beverage, oil, pharmaceutical, and industrial sectors. Backed by decades of engineering expertise and a shared legacy with Chadha Sales Pvt. Ltd., we combine innovation with manufacturing excellence to deliver reliable, precision-built machines trusted in over 40 countries.

Operating from our state-of-the-art facility in Sonipat, Haryana, we manufacture a wide range of separators under the Lakshmi brand—offering capacities from 60 LPH to 5000 LPH.

Each machine is designed to improve product quality, reduce processing time, and minimize labor.

Our strength lies in our attention to detail—especially the in-house dynamic balancing of the separator bowl, the most critical component. Whether it’s customized specifications or industrial-grade designs for non-dairy applications, Noe Tech equipment is built to deliver consistent performance and long-term value.

40+ countries, thousands of installations.

Advanced centrifugal technology for exceptional accuracy.

Tailored specifications for all your needs.

Dynamic bowl balancing for maximum performance.

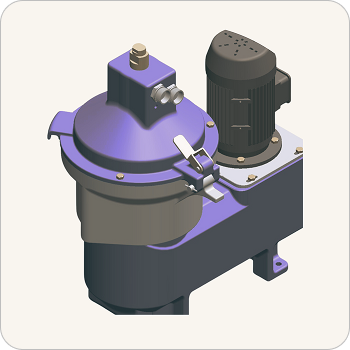

Our AE Series separators are trusted by dairies for reliable cream separation, with models engineered for small to mid-scale production. Featuring hygienic construction, pump-fed operation, and consistent bowl speeds of up to 7200 RPM.

Designed for the clarification and purification of industrial liquids including coolants, oils, and washing fluids. The DP series offers reliable performance in challenging environments.

The NTN series offers robust performance for larger-scale industrial operations across sectors like metalworking, petrochemicals, and marine. Built for reliability under continuous use.

Our AEO Series cream separators are designed for seamless integration into continuous milk processing lines. Built with a focus on hygiene, reliability, and operator ease, these electric-driven online models come in capacities up to 5000 LPH.

In-house bowl balancing for superior separation.

Built with premium materials for long-lasting operation.

Optimized workflows to save time and elevate product quality

Expert technicians and comprehensive customer service for all your needs

We manufacture separators for applications across industries including:

Have questions or need a custom solution? Reach out now!

© 2025 Noe Tech International Pvt. Ltd. All Rights Reserved.

AE-11: 325 LPH capacity with SS cladding and pump feeding

AE-31: 2000 LPH capacity, lubrication-free drive, food-grade build

DP-100: Compact design with 400ml bowl volume

DP-500: Versatile for fluid clarification with high-speed motors

NTN-3: Heavy-duty configuration with centripetal pump discharge

NTN-4: 2.7L bowl, 1.9L solids holding, up to 3400 RPM

AEO-1: 1000 LPH capacity, hermetic feed, centrifugal clutch system

AEO-3: 3000 LPH capacity, manual cleaning, high-speed bowl up to 8000 RPM

AEO-5: 5000 LPH capacity, stainless steel construction, 7.5 HP motor